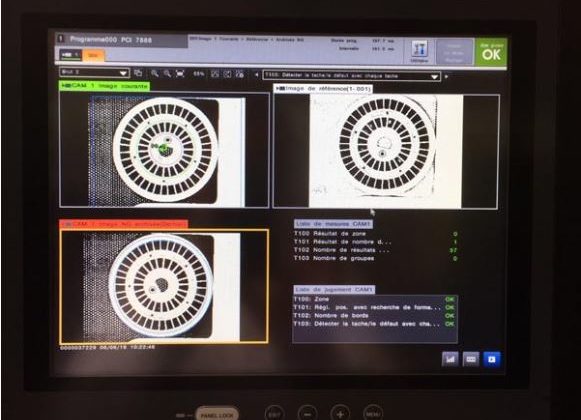

Post operations

Vallotech has developed a range of different, post-production machining operations to reduce tolerances on the functional areas of our components to within the range of a few microns:

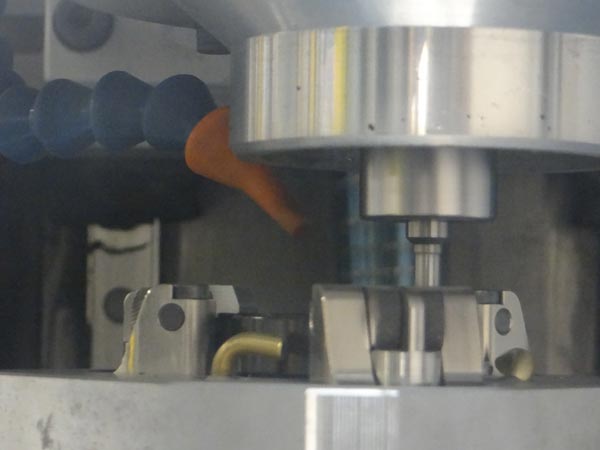

Milling:

Milling is used for pump components, to reduce clearances to a few microns, allowing us to ensure optimum operational performance. These milled, phenolic moulded components are used instead of and in preference to machined metal parts. We produce literally millions of high-reliability components every year using this technology.

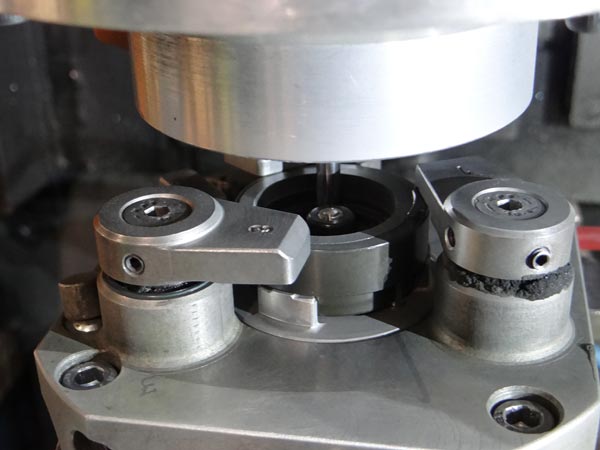

Lapping:

This process permits us to obtain stable production, controlling thicknesses to tolerances within a few microns and with a Cpk greater than 1.67. These close tolerance parts allow our customers to rely on their exceptional accuracy, guaranteeing the optimal functioning of the complete assembly. We deliver more than 30 million lapped parts every year, worldwide

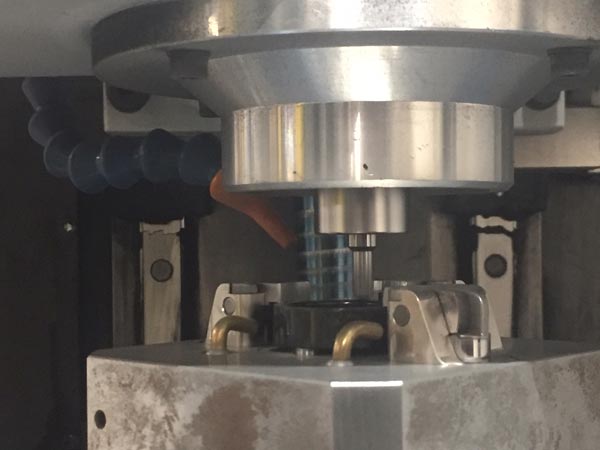

Centreless Grinding :

Thermoset parts are used to replace machined aluminum elements. To achieve the necessary concentricity and required surface finish, Vallotech uses centreless grinding. The finished parts offer dimensional accuracy and surface consistency equal to or better than aluminum, without any additional treatment or processing.