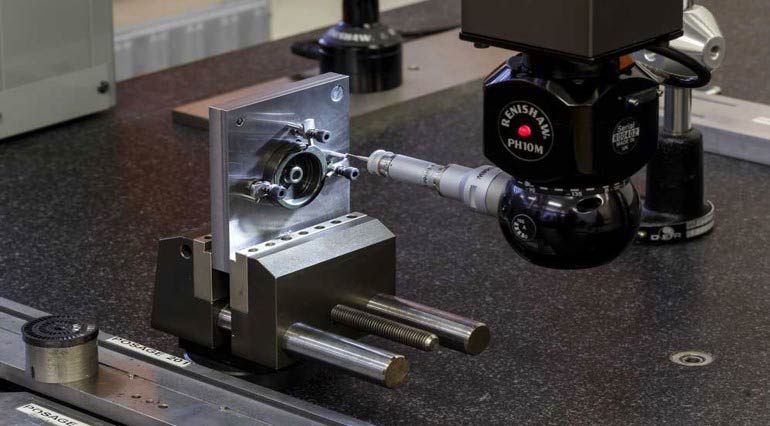

Measuring

Controlling mechanical and dimensional tolerances to within a few microns requires not just the right measuring equipment and control systems, but also using them in the right way and at the right point in the process. At Vallotech we use the very latest measurement technologies:…

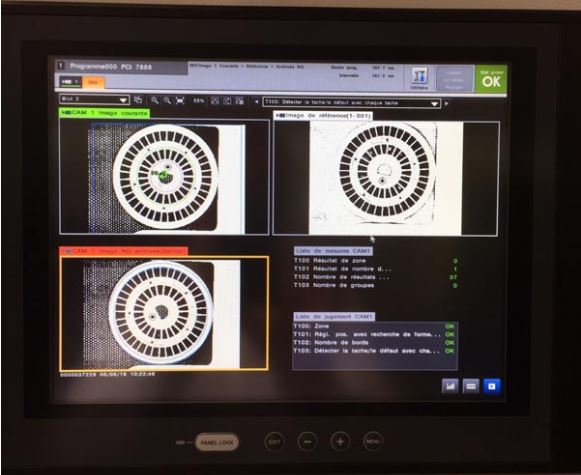

Visual inspection

Visual assessment of component and operational quality is carried out either directly or by camera, depending on the point in the production process, the physical risk and the risk of error. Risk levels are carefully assessed and monitored depending on the processes and the specific…

Washing rinsing

Some post-operations can generate surface contamination, so we have implemented a comprehensive washing-rinsing-drying process to ensure that components fulfil our customers’ most stringent requirements.

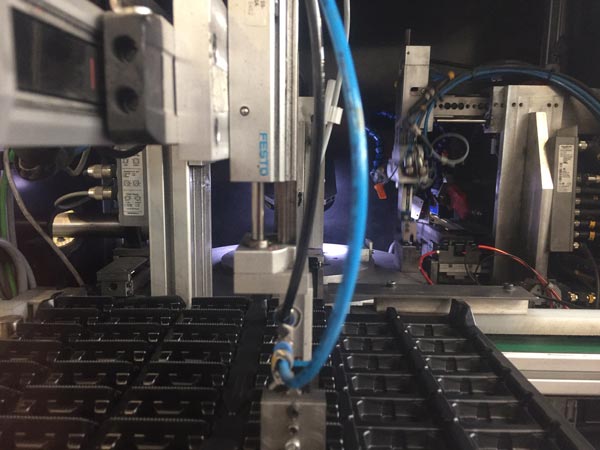

Automated assembly

There is more to producing consistent parts than good design. As an integral part of the production process, we create fully automated production lines, allowing the continuous assembly of multiple parts into finished sub-assemblies or components, including online quality controls such as visual inspection, functional…

Post operations

Vallotech has developed a range of different, post-production machining operations to reduce tolerances on the functional areas of our components to within the range of a few microns: Milling: Milling is used for pump components, to reduce clearances to a few microns, allowing us to…

Post curing

Thermosetting or thermoplastic resins used in technical applications require precise post curing in order to ensure the dimensional stability of the end product. Working with specialist chemists, Vallotech develops precision post-treatment profiles for each of the materials that we use, ensuring complete consistency across production…

Overmolding

With this process, we achieve the moulding of interlocking or concentrically mounted parts, to include different materials or properties within a single component, allowing us to create a perfect seal between the two, or to create a protective barrier to prevent chemical or electrical damage….

Injection molding

At Vallotech we have been moulding thermosets since the beginning of the 20th century, resulting in a phenomenal level of experience and expertise. The mouldable nature of thermosets allows us to produce parts with significant thickness and considerable dimensional stability, offering welcome flexibility when it…

Transformed materials

Thermosets are highly stable, three-dimensional structures with excellent thermo-mechanical and chemical resistance, the essential dimensional stability to obtain micron precision and a very good electrical resistance. With their specific qualities, these resins are increasingly used to replace metal, reducing weight and often increasing lifespan. We…